Next Generation Feed Roller Maintenance

Next Generation Feed Roller Maintenance Objective

To clean the rollers of dirt and dust that settle upon the grooves of the roller and impede the roller’s ability to grab and feed tickets.

Preparation

- Empty the columns

- Turn off and unplug the machine

Materials

- Small, soft and durable cloth/towel (required)

- Warm water (required)

- Distilled white vinegar – with an acidity of 5-8% (optional)

- 70% isopropyl rubbing alcohol (optional)

- Soft-bristle toothbrush (optional)

Procedure

Use the cloth and a small amount of water to clean the rollers in the following manner:

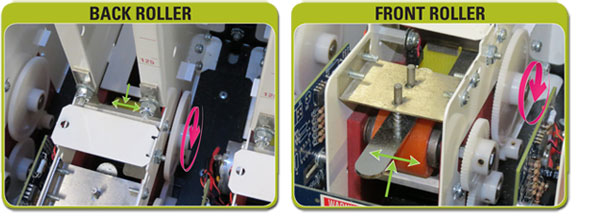

- While turning the big column gear by hand (red arrows), push down with the damp cloth on the roller and swipe from side to side (green arrows).

- Inspect the cloth, if there is dirt on the area of the cloth that was pushed against the roller, use a clean section of the cloth and repeat the above process.

- Continue until the roller no longer deposits dirt on the cloth.

Notes

- Arrow International recommends first using a cloth and warm water. For persistent stains, substitute white vinegar in place of water. Rubbing alcohol can also be used in place of water but it may dry out the rollers faster than white vinegar, so, the latter is recommended.

- Once the grooves on the rollers wear out, no amount of cleaning will restore the rollers to their original function. Rollers are wear and tear parts – similar to car tires – and if the rollers are clean, but smooth, they need to be replaced.

- CAUTION: do not turn on the machine until you are certain that all liquids have evaporated

Scheduling

Depends on machine usage and customer preference. Some options include:

- Only when dispensing problems begin to manifest, and columns are not dispensing tickets properly

- Whenever loading a new deal of tickets (since the columns are already empty)

- A set schedule depending on the usage of the machine (for example every 3 weeks, or every 2 months)